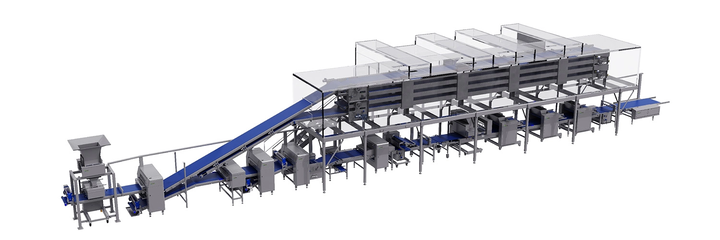

Automatic Pizza Forming Line for High-Speed, Scalable Pizza Production

Posted by Hengjiang intelligent

Filed in Card Games 1 view

As global demand for frozen pizza, ready-to-bake pizza, and fresh takeaway pizza continues to surge, food manufacturers are under increasing pressure to scale production while maintaining consistency, hygiene, and operational efficiency. Hengjiang Intelligent Technology Co., Ltd. addresses these challenges with its Automatic Pizza Forming Line, a high-precision, fully integrated solution engineered for modern, high-output pizza factories.

Designed around automation, flexibility, and food safety, this advanced pizza forming production line enables manufacturers to produce pizzas of multiple sizes and formats with impeccable stability at high speeds, making it an ideal choice for both large industrial plants and fast-growing commercial bakeries.

Built for the Future of Automated Pizza Manufacturing

The Automatic Pizza Forming Line reflects the latest trends in Industry 4.0 food processing, where intelligent equipment, repeatable accuracy, and hygienic design are no longer optional—but essential.

By replacing manual forming and semi-automatic processes, Hengjiang’s solution dramatically reduces labor dependency while improving product uniformity and throughput. This makes it especially suitable for:

-

Frozen pizza manufacturers

-

Central kitchens and commissaries

-

Chain restaurant supply facilities

-

OEM pizza brands scaling global distribution

High-Precision Dough Forming for Consistent Pizza Quality

One of the most critical factors in pizza production is dough consistency. Variations in thickness, diameter, or texture directly affect baking performance and consumer experience.

The Automatic Pizza Forming Line uses precision-engineered forming modules to ensure:

-

Uniform dough thickness across the entire base

-

Perfectly round pizza shapes

-

Stable weight control for each piece

-

Repeatable results regardless of production speed

This high level of precision ensures every pizza meets strict quality standards—batch after batch, shift after shift.

Flexible Production for Multiple Pizza Sizes and Formats

Responding to market trends such as customizable pizzas, mini pizzas, family-size pizzas, and private-label SKUs, Hengjiang’s pizza forming line is designed with exceptional flexibility.

The system can be easily adjusted to accommodate:

-

Different pizza diameters

-

Varying dough weights

-

Thin crust, classic crust, or specialty bases

-

Diverse production requirements without lengthy downtime

This adaptability allows manufacturers to respond quickly to changing consumer preferences and seasonal demand without investing in multiple production lines.

High-Capacity Output with Exceptional Stability

Speed alone is not enough—true industrial performance requires stability at scale. Hengjiang’s Automatic Pizza Forming Line delivers high-capacity production while maintaining consistent accuracy and smooth operation.

Key performance advantages include:

-

Continuous, high-speed forming without deformation

-

Stable operation suitable for long production runs

-

Reduced mechanical stress for longer equipment lifespan

-

Optimized synchronization between forming stages

This combination of speed and stability helps manufacturers maximize output while minimizing waste and unplanned downtime.

Hygienic Design That Meets Global Food Safety Standards

With food safety being a top Google-trending concern in food manufacturing, hygienic equipment design is essential. Hengjiang places hygiene at the core of the pizza forming line’s engineering philosophy.

The system features:

-

Food-grade materials throughout product contact areas

-

Smooth surfaces that prevent dough buildup

-

Easy disassembly for thorough cleaning

-

Design compliant with international food hygiene standards

These features significantly reduce contamination risks and support compliance with HACCP, FDA, and CE-related hygiene expectations, making the line suitable for export-oriented production facilities.

User-Friendly Operation and Intelligent Control

Ease of operation is another major advantage of Hengjiang’s Automatic Pizza Forming Line. Designed with production efficiency in mind, the system integrates intuitive controls that simplify daily operation and reduce training requirements.

Benefits include:

-

Simple parameter adjustment for size and thickness

-

Stable automation that minimizes operator intervention

-

Reduced labor intensity and human error

-

Improved overall equipment effectiveness (OEE)

This intelligent design supports both experienced production teams and rapidly expanding operations.

Energy-Efficient and Cost-Effective Pizza Production

In an era where energy efficiency and production cost control are trending priorities, the Automatic Pizza Forming Line is optimized to deliver strong ROI.

By combining high output, reduced labor needs, and minimal material waste, manufacturers benefit from:

-

Lower per-unit production costs

-

More predictable output planning

-

Increased competitiveness in price-sensitive markets

Why Choose Hengjiang Intelligent Technology Co., Ltd.?

Hengjiang Intelligent Technology Co., Ltd. is recognized for its commitment to precision engineering, intelligent automation, and reliable food processing solutions. The Automatic Pizza Forming Line embodies this expertise, offering manufacturers a future-ready platform for scalable pizza production.

Key Advantages at a Glance

-

High-precision automatic pizza forming

-

Flexible production for multiple pizza sizes

-

Stable high-speed performance

-

Hygienic, food-grade design

-

Easy operation and maintenance

-

Ideal for frozen and fresh pizza production

Conclusion: A Smart Investment for Modern Pizza Producers

As global demand for convenient, high-quality pizza continues to grow, investing in advanced automation is no longer optional—it’s strategic. Hengjiang Intelligent Technology Co., Ltd.’s Automatic Pizza Forming Line provides the precision, flexibility, and reliability required to compete in today’s fast-moving food manufacturing landscape.

For producers seeking consistent quality, scalable output, and hygienic design, this pizza forming solution represents a powerful step toward smarter, more efficient pizza production.